Removing mold, dirt, dust, and rust from your machines is crucial if you want to expand their durability and if you want to make sure that everything is functioning correctly. The cleaning process can be extremely expensive and time-consuming. Because of this, we need to find better solutions for the maintenance process and learn how to protect every surface that we are cleaning while removing every excessive particle. In this article, we will give you more information about the laser cleaning machine, why you should use it, and what you can clean with it.

What makes it a good choice?

The first thing we’re going to talk about is why you would want to go with the laser cleaning machine instead of any other option. This process is going to help you remove any dirt, debris, rust, paint, and many other contaminants from a surface. It is an eco-friendly process that is a far better option than any other type of chemical product. Since it does not require chemicals, you are going to protect the environment and you’re also going to protect the surface that you are working with. We all know how easy it is to damage something just because you chose the wrong chemical or how easy it is to destroy something just because you decided to put too much pressure when using mechanical cleaning options.

The reason why more and more brands are going with laser cleaning machines instead of any other type of mechanical or chemical solutions is that this process is going to help you save a lot of time and ultimately a lot of labor. The whole process is much faster, the margin for error is much smaller, and the time needed for cleaning and maintenance is going to be reduced. You will be able to get the job done faster, and with ease, and you will not have to worry about damage to the surface.

Now, let’s see what you can clean with the laser cleaning machine and what are the limitations of this process. Keep on reading to find out why the laser cleaning machine is so commonly used, and check out hispeedlaser if you want to know more about the implementation of these devices.

What can you clean with it?

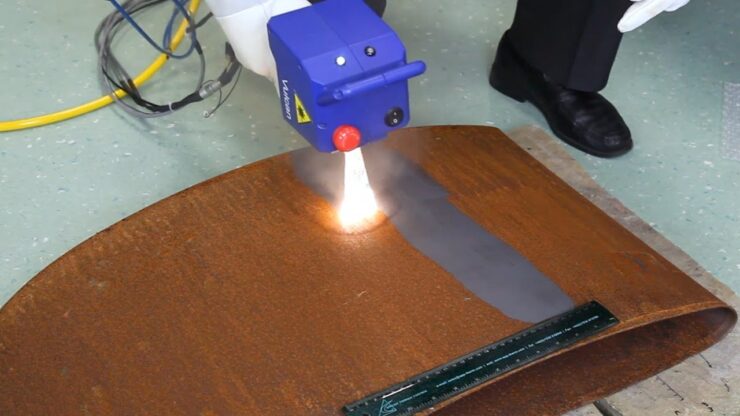

As you probably know, the laser cleaning machine is most commonly used to clean metal. This surface is the one that is most likely to get damaged with time and is the one that is most likely to rust especially if it’s not kept in the right conditions. Nevertheless, that does not mean that this is the only surface that you can clean with these devices, and now we’re going to explore how you can properly utilize the lasers and how they can help in your life.

The main thing that you need to know is that the beams work the best when it comes to dark and non-reflective surfaces. Because of this, the laser is the most effective when it comes to cleaning rust because rust is non-reflective and it is not light. The more reflective the surface is, the more difficult it is going to be to clean it with a laser.

The surfaces that you can clean using a laser are divided into metals and nonmetals. Metals that contain iron tend to rust, and this is the main thing why this device is used. If the metals do not contain iron, they do not rust. Laser, in these cases, can be used to remove the oxide coating. You can also use the laser to clean dirt, paint, grease, and mold. You should know that this device is used to remove even the thickest layers and even the most stubborn dirt.

When it comes to nonmetals, lasers can be used to efficiently remove any materials from non-metal surfaces without damaging the surface itself. The main thing that needs to be done before using a laser for a non-metal surface is to properly calibrate it if the laser is calibrated to clean a metal surface and it is used for a nonmetal one, this surface can easily be damaged.

You can use a laser to clean a ceramic surface, as well as natural stones, including concrete granite, and marble. Know that it is used to not only help remove dirt and dust but also to restore ornaments, building facades, statues, and so on.

Even though these devices are not commonly used to clean rubber and plastic, as long as you properly calibrate the laser, you can use it to clean this material as well. Keep in mind that if you choose to clean plastic or rubber with your laser machine, you have to check if this process is suitable depending on the exact type of material. In some cases, you may end up damaging or melting the substrate.

Because of this, the laser cleaning process is used in many different industries, especially the ones where chemical products are restricted, and where the main thing and cleaning process takes too much time when used in the traditional way. This process is currently most commonly used in the automotive industry, aerospace, as well as oil and gas industries. The best thing about this is that the whole process can easily be automated and there is no need for a human worker to do all the hard work. Things can be set up and the only thing a human worker would need to do is check if everything is coming along properly.

As you can see, every material that isn’t too dark and too light and every material that can stand a little bit of heat without getting damaged is suitable for laser cleaning. This includes inox, cast iron, steel, aluminum, Chrome coating surfaces, wood, stone, some type of glass, as well as some types of plastic and rubber. Make sure that you know how to use your machine properly, that you know how to calibrate it correctly, and that you are using the right device for your specific needs.