Did you know that printing is one of the oldest crafts on Earth? Here’s a little lesson in history.

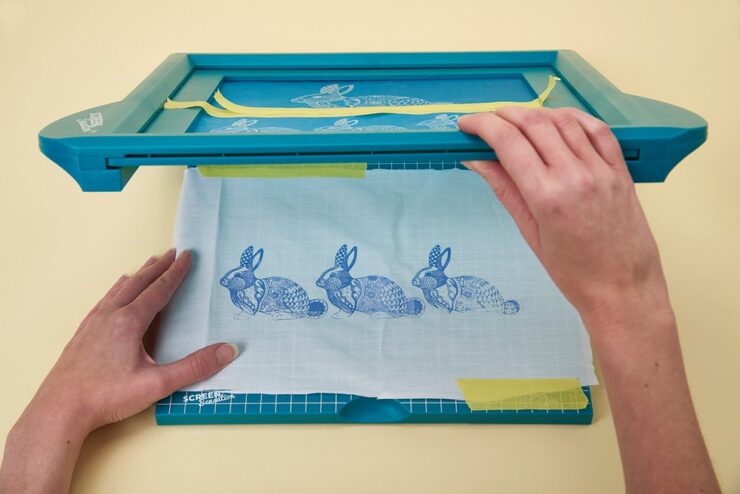

Silk printing is a printing technique that is a few thousand years old, and was created in China as one of the methods of painting silk. Back then, the technique was based on pushing paint with a wooden or rubber squeegee onto a substrate (textile, paper, etc.) through silk stretched on a wooden frame, on which there is a template with the pattern we want to reproduce. Today, instead of real silk, various artificial materials stretched on a wooden or aluminum frame are used, which is why name screen printing is more often used. However, almost in its original form, it is still used today.

But as is the case with everything, through the years technology found a way to simplify the process. Today, except for rare artists, who make the stencil manually by directly painting the silk stretched on the frame, a photo process is used for this purpose, which copies the stencil on the film onto a special photosensitive substrate that is applied to the silk. The film itself can be made using a computer or printer, or what is still very common in artistic graphics, by drawing a template on a transparent film with special red paint. In order for the silk screen printing to be as vibrant as possible, according to holdensscreen.com the selection of quality colors is very important.

Commercial and merchandise goods have also utilized this technique to make quality and unique goods, from T-shirts to baseball hats. More and more companies have started to appreciate garments of good quality, hence started screen printing on large scales as of 2016. So, if you’re searching for a technique to utilize and make quality goods, we highly suggest you try this one.

There is a catch, however, as not all materials will serve the purpose. That’s why before you opt for it, you need to learn which ones are the best absorbing ones, that will hold the print for the longest periods of time. As most of the materials we find on the market today are a mixture of different ones, specific characteristics of each major type should be studied. We should also note that natural ones are not the only type of material that can work for screen printing, because there are a lot of synthetic ones as well.

Here is where our article will help you. We have assembled a list of the best fabrics to use for this kind of printing and to help you pick the right material. Read below.

1. Cotton

Natural fabrics are the healthiest for our skin, and therefore cotton is always the first choice of many. Compared to other materials, its biggest advantage is that it allows the skin to breathe, absorbs moisture better, and regulates heat. This fabric is considered one of the most durable types. It does not tear easily and can withstand the strongest power of the washing machine or frequent hand washing. It also rarely causes allergic reactions, and wearing cotton is often recommended for those with skin allergies. Therefore, can be the best choice for this technique, especially because of its absorbing power. There are some drawbacks, as well. They mostly include a tendency to shrink over time.

2. Silk

It’s not called silk screen printing without a good reason. One of the characteristics of this material includes extreme smoothness. Because of it, the risk of the design being uneven on the surface is at a minimum, compared to other types of material.

Just like all materials, it does have flaws, and the biggest one is absorption. It simply cannot absorb the color well, making the print look slightly muted, or pastel. Another flaw is the price. As you probably know it has always been one of those very expensive materials, and if you’re printing merchandise goods, you’ll need quite a budget.

3. Wool

Being thicker than most fabrics we use today, it makes it a perfect material for absorbing colors and printing using this technique. There’s a catch, though, and it includes a challenge as well – making sure the ink chosen for the technique is absorbed evenly in every wool item. Another flaw of this material is that it can be felt over time.

4. Linen

One of the natural materials with great absorbing power, and excellent for this technique is linen. The Egyptians valued this fabric so much that they called it moon weaving. It is a natural material that is difficult to obtain, but it is equally difficult to make things from it. However, the final product you get trumps everything. Endurance, when it comes to carrying capacity and strength. Lightness and breathability when we wear light clothes. Of course, the price must round it off in the end.

5. Hemp

The material has become more affordable, and clothes from it are often made to order in limited editions. The range of applications is wide, including many products, up to thermal underwear. If you can find sources to supply you with enough of this material for silk printing products, they’ll be of great quality and value.

Different blends

As you probably know by now, in order to eliminate some of the flaws of certain materials, technology has found a way to mix natural and synthetic ones. The majority of blends are with polyester and nylon, in combination with a natural fabric.

These blends are in fact excellent for screen printing, especially when used on sweatshirts, for instance. They absorb well, they are also very long-lasting in this blend, and the risk of shrinking when it comes to cotton blend is minimized. Not to mention how comfortable they are for everyday wear.

So, we have provided you with a pretty detailed study of each material that can be used for screen printing. All you need to do now is decide which one will be your choice.